Seized Solid, Leaking Bad & Cracked Welds! Bobcat Auger Power Head Overhaul! 💪

Cutting Edge Engineering Australia

@cuttingedgeengineeringAbout

Welcome to our machining, welding & hydraulic repair workshop! RIGHTO GUYS! Kurtis & Karen here from Cutting Edge Engineering, we're a down-to-earth real life machining and fabrication workshop in Australia. We specialise in helping business in mining and earthmoving to keep their machines running smoothly. We love working on broken parts and the bigger the better! 💪 SEE IT IN ACTION! We upload new videos every week showcasing machining, welding, line boring, honing and all the other awesome stuff that goes down in our workshop. Learn how we tackle different projects and see the satisfaction of creating something useful. JOIN THE COMMUNITY! Subscribe to stay updated on our latest jobs and projects! Follow us on Patreon for even more content and behind-the-scenes glimpses or find us on Tiktok, Facebook and Instagram for a chance to connect with us. WANT TO KNOW MORE? Check out some of our websites below!

Video Description

We’ve got a seriously worn-out Bobcat auger power head off a 5 tonne excavator in the workshop and it’s not in great shape. From a completely destroyed seal and a rusted, seized pin to cracked welds and a worn output shaft, this unit needs some serious attention before it can get back to work. We start with tearing down the housing, but the pin is rusted solid — so it’s out with the oxy torch to cut through the sides and free up the head bracket. Once we’ve got the power head out and disassembled we find the blown seal and sure enough, the output shaft is worn down and will need a precision lathe repair to fit a custom-made seal. The seized pin doesn’t give in easily, even with heat and a hammer — so it’s onto the 150 tonne hydraulic press to show it who’s boss. After that, we repair the cracked housing welds and add some extra strength with some extra welds. Once the new seal arrives, we dial in the shaft on the lathe and machine it back to match — but there’s no room for error here. Overcutting means another 3-day delay. With that sorted, we turn and drill a brand new pin, then reassemble everything with new seals. This one’s ready to go back to work — and we made sure it’ll last for years to come. Join our channel: We upload new videos every Friday at 5pm AEST! If you want to see more of our videos click LIKE & SUBSCRIBE! You can subscribe to our channel here: https://bit.ly/ceesubscribe Want Early Access & Ad Free videos?? Join our Patreon Community: https://www.patreon.com/cuttingedgeengineering Official CEE Merch shop: https://www.ceeshop.com.au Check out our CEE Amazon store and explore our favourite finds that we use in the workshop: https://www.amazon.com/shop/cuttingedgeengineeringaustralia To see more follow us on online here: TikTok: https://vt.tiktok.com/ZSdHhtN4h/ Instagram https://instagram.com/cutting_edge_engineering Facebook https://www.facebook.com/cuttingedgeengineeringaustralia/ About Us: We're a down-to-earth real life machining and fabrication workshop in Australia. We specialise in helping business in mining and earthmoving to keep their machines running smoothly. We love working on broken parts and the bigger the better! We upload new videos every week showcasing machining, welding, line boring, honing and all the other awesome stuff that goes down in our workshop. Learn how we tackle different projects and see the satisfaction of creating something useful. Subscribe to stay updated on our latest jobs and projects! Follow us on Patreon for even more content and behind-the-scenes glimpses or find us on Tiktok, Facebook and Instagram for a chance to connect with us. #australianmachinist #machineshop #machinist

Revive Your Bobcat Auger Today

AI-recommended products based on this video

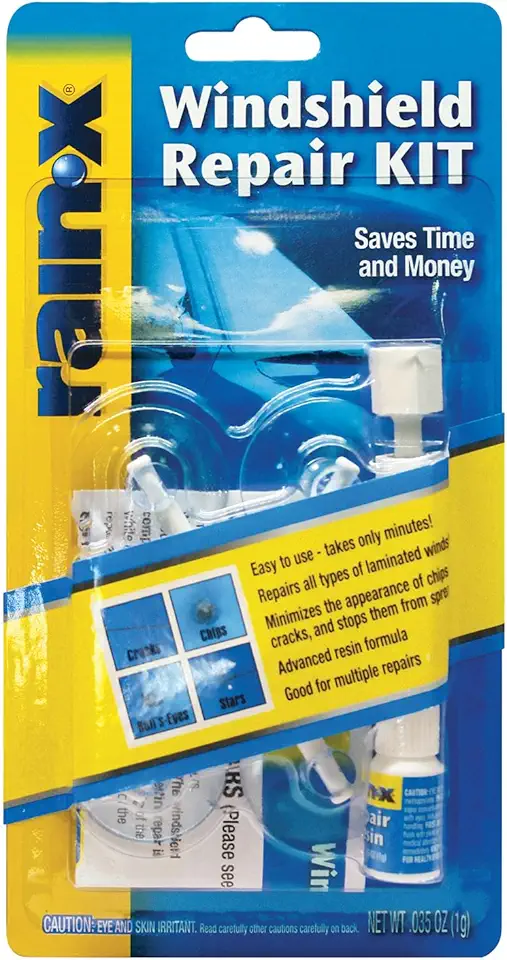

Rain-X 600001 Windshield Repair Kit - Quick and Easy Durable Resin Based Windshield Repair Kit for Chips and Cracks, Good for Round Damage Below 1" in Diameter and Cracks Smaller Than 12" in Length

Tub, Tile and Shower Repair Kit (Color Match), Hupeyna Porcelain Repair Kit, Bathtub Repair Kit for Chips Dents Cracks Holes Scratchs, etc. Fiberglass Repair Set - Offer More Color Options

Replacement Toothbrush Heads 10 Pack for AquaSonic Black Series and Vibe Series Electric Toothbrush